Product introduction:

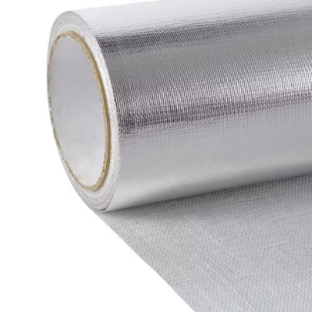

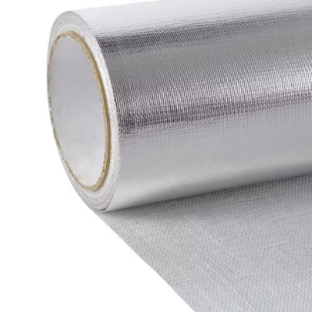

Using a unique advanced composite technology, the surface of the composite aluminum foil is smooth and flat, high light reflectivity, high tensile strength in vertical and horizontal direction, good sealing performance, the surface is treated with special anti-corrosion coating, the anti-corrosion performance is greatly improved, and the polyethylene hot paste method is used, no composite adhesive is required. It avoids the hidden danger of corrosion and mildew on the surface of aluminum foil caused by residual moisture or solvent of adhesive in the composite process, and directly hot pressing composite can save composite adhesive and save the cost of veneer composite. The water vapor permeability is smaller, which enhances the water vapor barrier effect. The heat-sealed polyethylene film of glass fiber cloth aluminum foil is thicker than the general panel, the water vapor permeability is smaller, the water vapor barrier effect is better, and the glass wool and thermal insulation materials are reliably protected.

| Parts of Aluminum foil coated | |||

| Type | thickness(mm) | Total weight (g/m2) | coated sides |

| AL-7628 | 0.2 | 220 | Single/Both sides |

| AL-3732 | 0.43 | 450 | |

| AL-666 | 0.6 | 700 | |

| AL-2025 | 0.75 | 850 | |

| AL-M30 | 1.5 | 1080 | |

| AL-FG105T 0.8mm | 0.8 | 600 | |

| AL-FG105T 1.0mm | 1.0 | 800 | |

| AL-FG105T 1.5mm | 1.5 | 1000 | |

| AL-FG105T 2.0mm | 2.0 | 1300 | |

| AL-FG105T 3.0mm | 3.0 | 1800 | |

Features:

1. heat radiation reflection

2. Good strength and wear resistance

3.Excellent water resistance and steam resistance

4. Flame retardant and high temperature resistant

Application scenario:

It is mainly used for insulation materials of heating and cooling equipment pipelines and the outer protective layer of noise reduction and sound insulation materials on buildings, and can also be applied to moisture-proof, fog-proof, fire-proof and anti-corrosion packaging materials of export equipment.